Technicial Specifications

Technical Spesifications

| Machine Type : | Shock Absorber |

| Inner Drum Length : | 3,20 m |

| Inner Drum Diameter : | 400 mm |

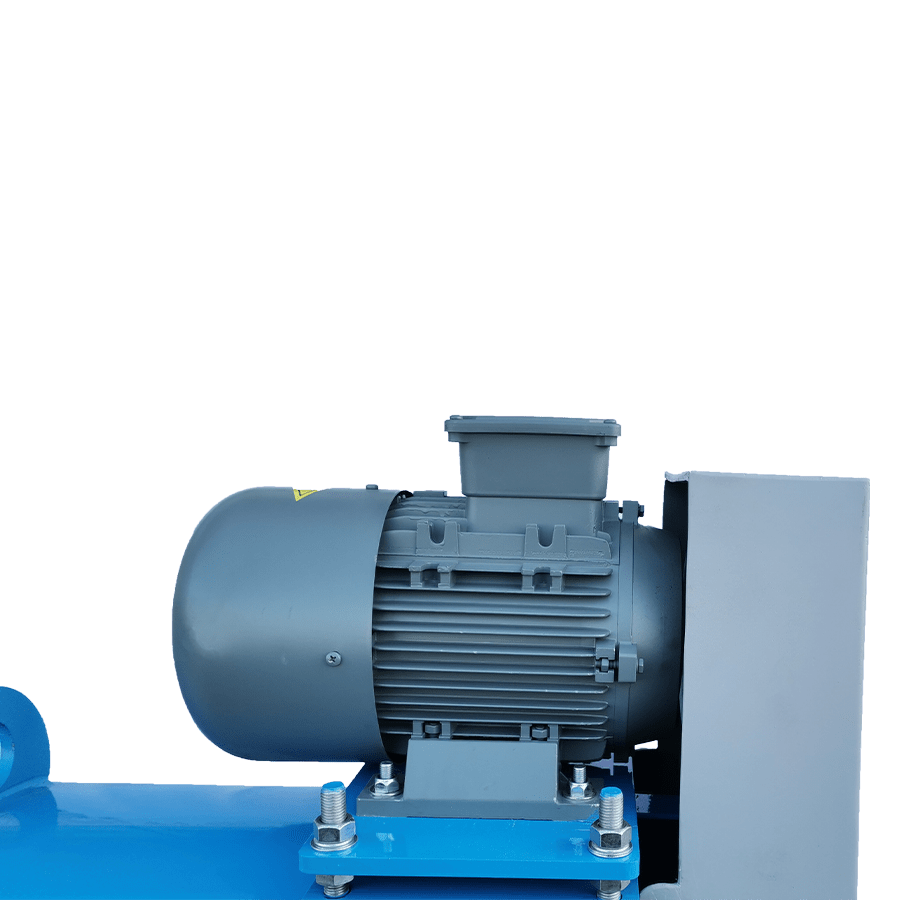

| Engine Cycle : | 1400 rpm/min |

| Roll Cycle : | 1200 rpm/min |

| Engine Power : | 7,5 (kW) |

| Voltage : | 380-50 (V-Hz) |

| Chrome Thickness : | 3 mm |

| Hole Diameter : | 1,5 mm |

| Carpet Wringing Capacity : | 100 m2/hour |

| Weight : | 675 kg |

| Dimensions : | 110x375x155 |

General features

Easy to use in all areas thanks to its silent and vibration-free operation.

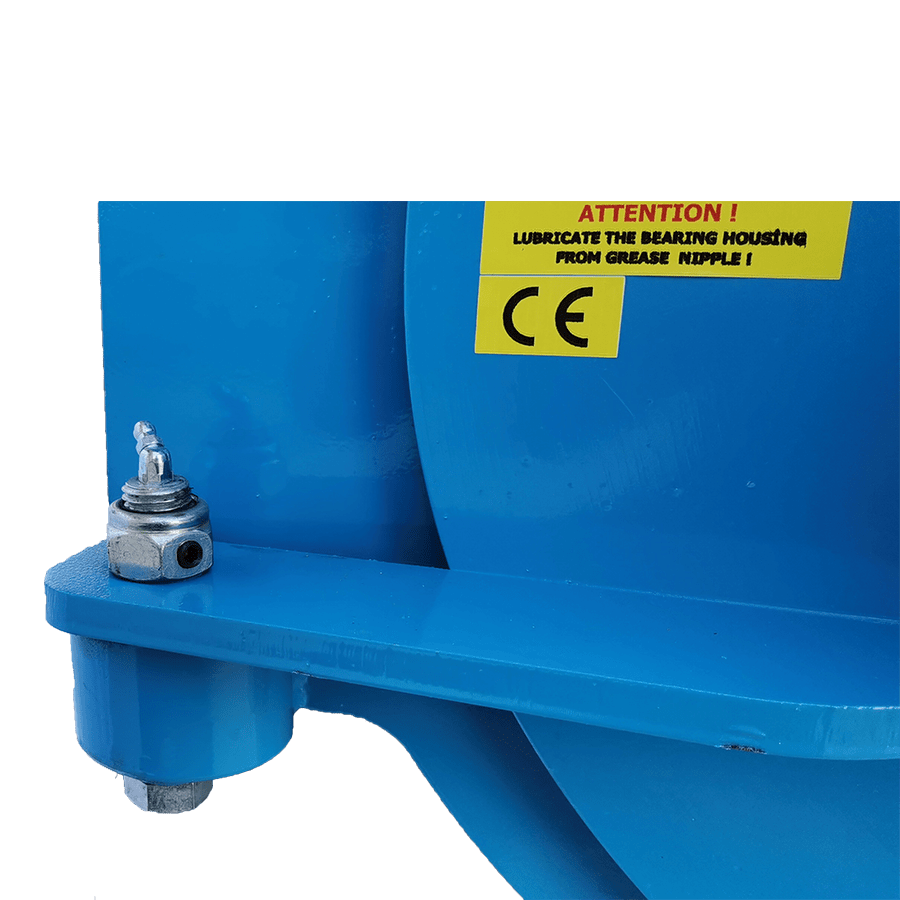

Special shock absorbers are used to prevent shaking.

3mm thick 304 quality chrome drum is used on the machine.

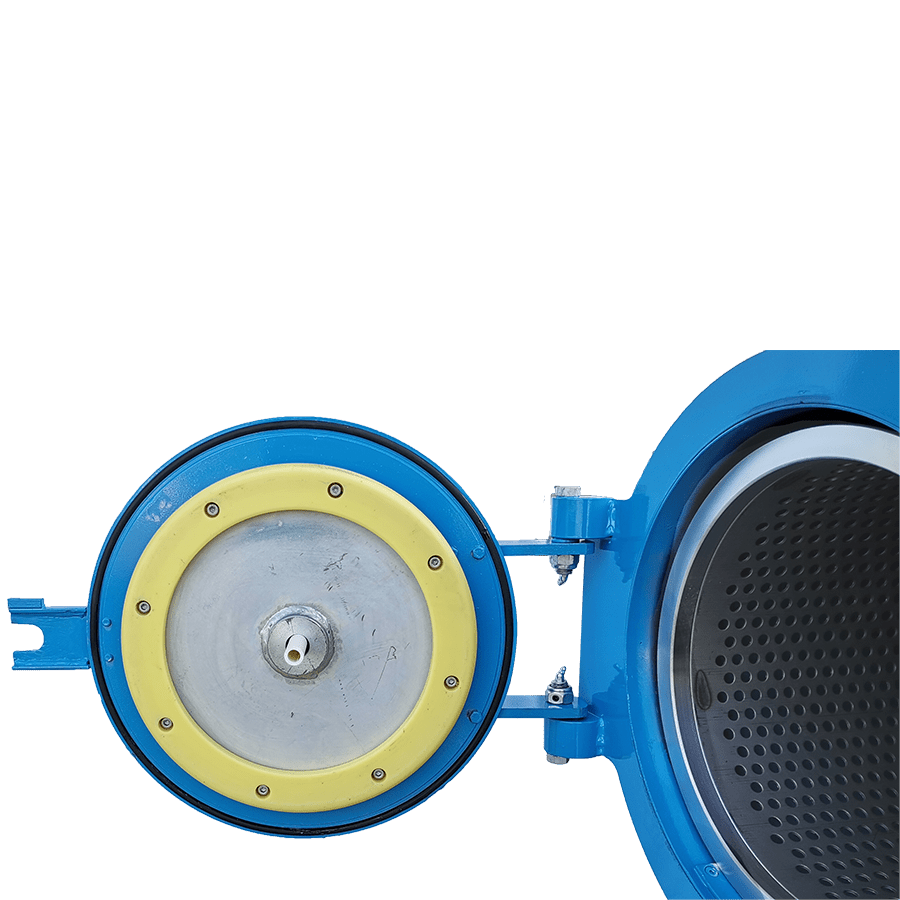

There is a cestamite system that provides the longest life between the drum and the lid.

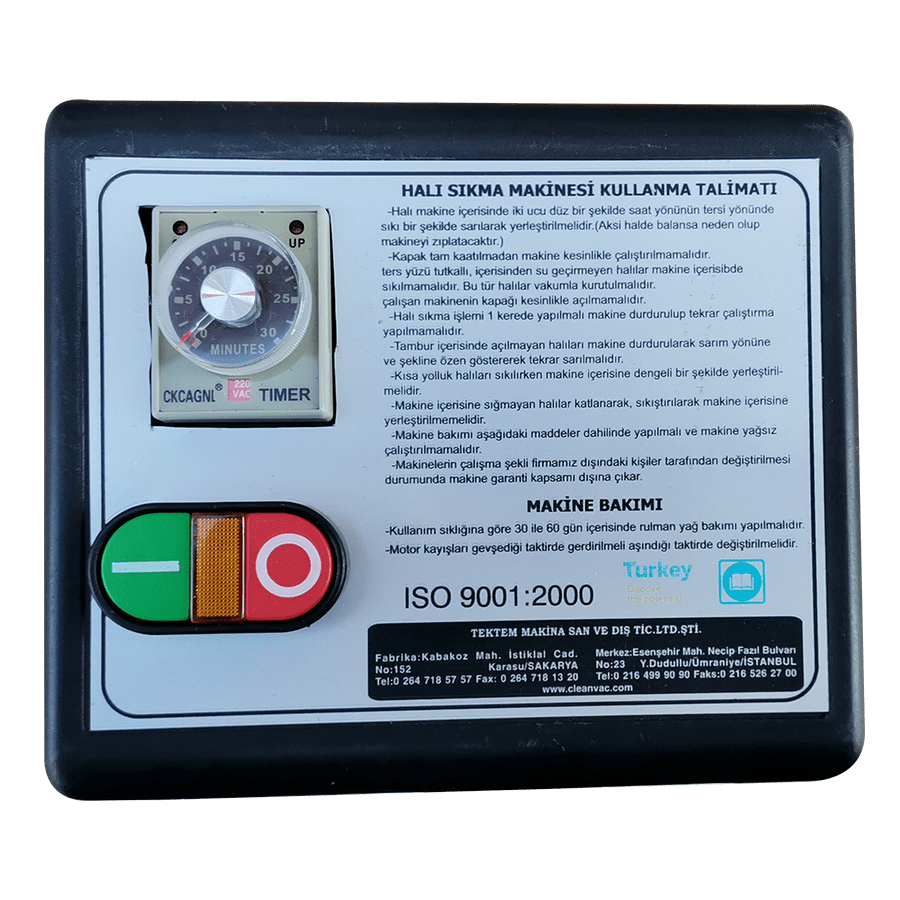

An external electrical panel is used for both work safety and time saving.

With its high cycle, it provides 98 percent dryness in as little as 1.5 minutes.

The strongest vibration-receiving feature thanks to the special shock absorber system

With its 550 kg weight, it shows the highest resistance in case the carpets do not open.

With the water inlet on the cover, it can be rinsed together with the spinning process.

It gives the best results on all kinds of carpets with its 40 mm drum diameter.

Carpet wringing machines are an indispensable assistant of industrial carpet washing businesses.

For this reason, there may be differences in the features and dimensions of carpet spinning machines.

In our CLEANVAC RL 1400 A 3.20 model, which is only one of the shock absorber carpet wash machines,

The motor power reaching 1400 revolutions per minute and the roll speed reaching 1200 revolutions per minute together ensure that the washed carpets are squeezed out of moisture up to 98 percent.

With its 5.5 kW engine power, it can offer exactly what is desired.

With a weight of 550 kg, the vibration caused by the engine power is absorbed and the machine is prevented from moving.

With this machine, carpets up to 320 cm can be easily wringed.

With its 380 V voltage value, it is suitable for use anywhere that uses an industrial electrical network.

CLEANVAC RL1400 can be easily transported with its shock absorber structure.

You can press clean water through the hose from the water tap on the front of the cover.

Steam is evacuated from the air holes on the top of the machine.

Water is evacuated from the 60 pipes at the bottom of the machine.

CLEANVAC RL1400 Lid grip system.

The machine works silently and without vibration.

The pipe type machine does not cause any damage to the carpet due to the way of squeezing the carpet roll.

98 percent dryness is provided in the carpets that are squeezed with this machine.

The machine has a carpet rinsing machine feature.

It helps to achieve perfect fringe cleaning by preventing water from flowing through the eaves during drying.

Time and labor efficiency increases.

No detergent residues.

Carpets do not have problems such as deformation or breakage.

Since the carpets do not stay damp for a long time, there is no bad smell in the carpets.

This appliance is designed for carpet drying purposes only.

Using it for other purposes may have dangerous consequences.

According to the regulations, after the electrical connection is made, the carpet should be placed in the drum with both ends equal and in the direction of rotation.

Otherwise, the machine may jump due to the balance and harm itself, people and the environment.

In this way, after the carpet is placed, the machine is activated with the help of the on-off button.

After working for the desired time, it is stopped, when the drum stops turning completely, the cover is opened and the carpet is taken out and left to air for a while.

With nearly 40 years of industry experience and wide technical service network, we have been providing the best service to our users since our establishment.

We provide support on the subject both in pre-sales and after-sales processes.

You can get detailed information about the prices of Cleanvac carpet centrifuges from our company.

About Product

Carpet centrifuges are an indispensable assistant of industrial carpet washing businesses. For this reason, there may be differences in the features and dimensions of carpet wringing machines. In our chrome 1400 A model, which is just one of the types of carpet centrifuges with shock absorbers, the motor power reaching 1400 revolutions per minute and the roller speed reaching 1200 revolutions per minute together with it, ensure that the washed carpets are wringed out of moisture up to 98 percent. With its 5.5 kW / 7.5 horsepower engine power, it can offer exactly what you want. With a weight of 710 kg, the vibration caused by the engine power is absorbed and the machine is prevented from moving. With this machine, carpets up to 320 cm can be easily wringed. With its 380 V voltage value, it is suitable for use anywhere that uses an industrial electrical network. Due to the fact that it has a shock absorber, the vibration experienced during the tightening process is absorbed and offers a quiet operation. Hourly squeezing capacity is 100m2. It has dimensions of 110x450x155 cm. You can press clean water through the hose from the water tap on the front of the cover. Steam is evacuated from the air holes on the top of the machine. Water is discharged from the Ø60 pipes at the bottom of the machine.

Lid grip system

• The machine works silently and without vibration.

• Tubular type machine does not cause any damage to the carpet due to the way of squeezing the carpet.

• 98 percent dryness is provided in the carpets wrung out with this machine.

• The machine has a carpet rinsing machine feature.

• It helps to achieve perfect fringe cleaning by preventing water from flowing through the eaves during drying.

• Time and labor efficiency increases

• No detergent residues

• Carpets do not have problems such as deformation or breakage.

• Since the carpets do not remain damp for a long time, there will be no bad odor on the carpets.

User Comments

User Comments alanına henüz içerik girişi yapılmadı.

FAQ

| Should Carpet Centrifuges Be Preferred With Shock Absorber Or With Wheels? |

| Every business has its own unique needs. These needs may vary according to the field of study. In cases where it needs to be moved continuously, carpet wringing machines with wheels may be the best choice, and in areas where it can stay at a fixed point, carpet wringing machine with shock absorber can be preferred. In order to overcome this situation, you can get effective information from our customer consultants. |

| What Should Be Considered While Buying a Carpet Centrifuge? |

| Recommended machine speed should be at least 1200 and above. Thus, it may be possible to reduce humidity by up to 95 percent. The thickness of the drum should be 3 mm and chrome. Thus, healthy squeezing takes place without tiring the machine. In the selection of the machine, the dimensions vary according to the carpet sizes that the people of the region generally use. |

| Does Carpet Centrifuges Work Quietly? Is it suitable for use under the building? |

| The drum balance is taken on special benches, and it is mounted to the machine as 0 balance with the latest system. The weight and quality of materials such as flanges and bearings used in the cover are the most important factors in reducing noise and vibration. The system we use is suitable for indoor machine use. |

| Does It Dry The Carpet Immediately? What is Average Time? |

| It provides 95 percent dryness in 2-3 minutes with real 1200 cycles. There is a timing option on the board we send next to the machine. |

| What are the Advantages of the Carpet Centrifuge with Shock Absorber According to the Wheel Model? |

| The first link of the shock absorber system is the shock absorber itself, systems such as bellows are considered inferior quality in this system and are not as effective as a shock absorber in preventing vibration. We minimize the vibration with the shock absorber and thick spring supported system. This means minimum downtime and maximum machine life. |

| What is the Material Used in the Cover? |

| We use cestamite material that prevents wear in the cover system. This system does not deform as quickly as the iron flanged system found in its counterparts and does not cause problems such as iron dust and oil in the machine mouth. |

| What is Drum Quality? |

| Instead of the 2.5 mm and two-piece drum in its equivalents, we use a 3 mm thick original 304 chrome quality drum. Thanks to its thickness, it does not cause deformations such as explosion, and it is in the best balance with its composition from one piece of sheet metal. |

| Can the Carpet that comes out of the Carpet Washing Machine with Foam be Thrown into the Wringing Machine? |

| Thanks to the rinsing system we use on the cover, while it wrings the carpet, it also removes the remaining chemicals from the carpet completely. |

| While Similar Carpet Centrifuges Have 38 cm Diameter Drum, Why Do You Have 40 cm Diameter? What is the advantage? |

| With the high diameter drum, the best results are obtained on long runners and thick carpets. In addition, with the thick ring we use at the drum mouth, the best drum protection is available. |

| Does it have a board or is it operated with the help of a charter? |

| There is an external electrical panel that can be mounted independently of the machine with a timer inside, thus maximizing work safety, and is timed. |

| What is the Advantage of High Engine kW? |

| More powerful engine is the most important factor in starting power and high kW provides better performance in heavy-duty machines. With the engine power, it generates 1400 cycles of power and transmits it to the drum as 1200 cycles with the pulley system we use. This is the most stable, complete working cycle. In this way, the carpets give the best drying results in a much shorter time. |

| Does Outer Sheet Rust? What is the material? |

| The outer sheet is a single piece of galvanized material and is first primed with epoxy ship primer and then baked in our special paint shops. The longest life is provided in this way. |

Warnings

-

*The carpet should be placed in the machine by tightly wrapping it in the same direction as a flat motor rotation direction. (Otherwise, it will cause the balance and make the machine jump.)

*The machine should never be operated before the cover is fully closed.

* Carpets with glue on the reverse side and waterproof inside should not be wrung in our machine. These carpets should be vacuum dried.

*The cover of the working machine should never be opened. * The lid should not be opened before the drum comes to a complete stop.

* Carpet tightening should be done at once, the machine should not be stopped and restarted.

* Carpets that are not opened in the drum should be stopped and rewound by paying attention to the winding direction and shape.

*Short runner carpets should be placed in the machine in a balanced way while being tightened.

* Carpets that do not fit inside the machine should not be folded and compressed into the machine.

*The machine should not be operated without grounding line.

*Mount the electrical cable suspended so that it does not touch the ground.

* Do not touch the machine during operation, do not change its location.

* Do not hang from the cable when removing the plug from the socket. Do not work with a damaged cable.

*If the operating mode of the machines is changed by people other than our company, the machine will be out of warranty.