Technicial Specifications

| Machine Type : | Shock Absorber |

| | |

| Inner Drum Length : | 4,20 m |

| | |

| Inner Drum Diameter : | 400 mm |

| | |

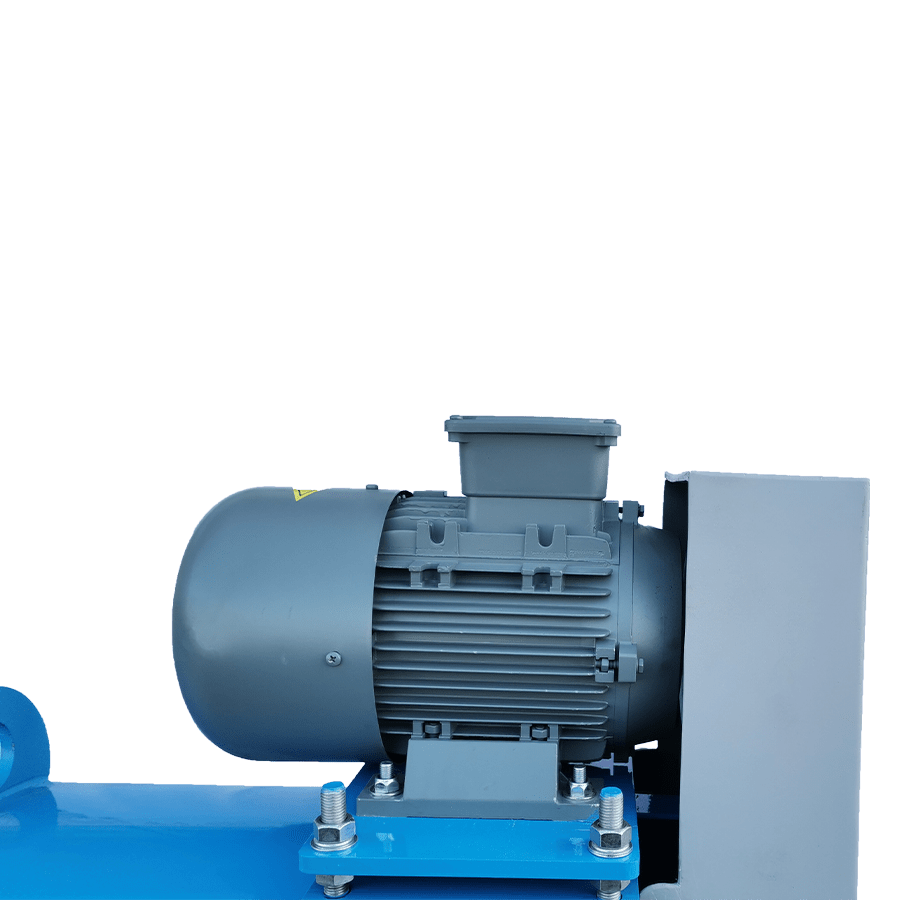

| Engine Cycle : | 1400 cyc/min |

| | |

| Roll Cycle : | 1200 cyc/min |

| | |

| Engine Power : | 5,5 /7,5 (kW/Hp) |

| | |

| Voltage : | 380-50 (V-Hz) |

| | |

| Chrome Thickness : | 3 mm |

| | |

| Hole Diameter : | 1,5 mm |

| | |

| Wringing Capacity : | 100 m2/hour |

| | |

| Weight : | 675 kg |

| | |

| Size : | 110x450x155 |

PURPOSE OF USAGE

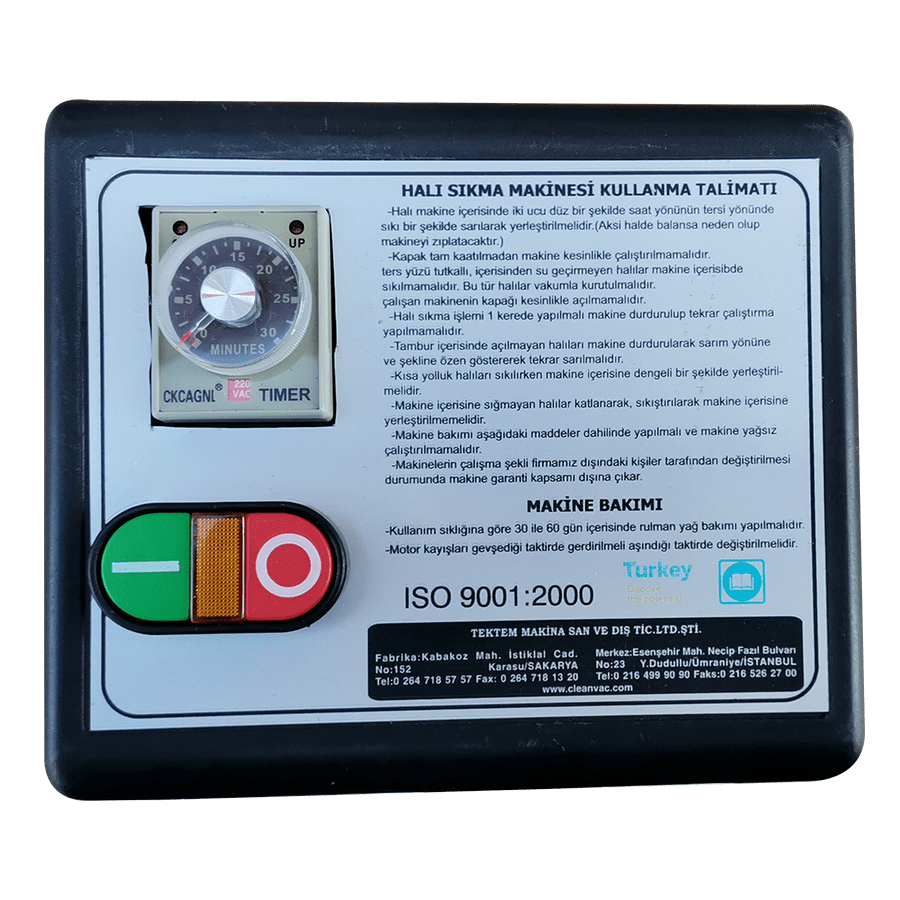

This appliance is designed for carpet drying purposes only. Using it for other purposes may have dangerous consequences. According to the regulations, after the electrical connection is made, the carpet should be placed in the drum with both ends equal and in the direction of rotation. Otherwise, the machine may jump due to the balance and harm itself, people and the environment. In this way, after the carpet is placed, the machine is started to move with the help of the on-off button.

MAINTENANCE RECOMMENDATIONS

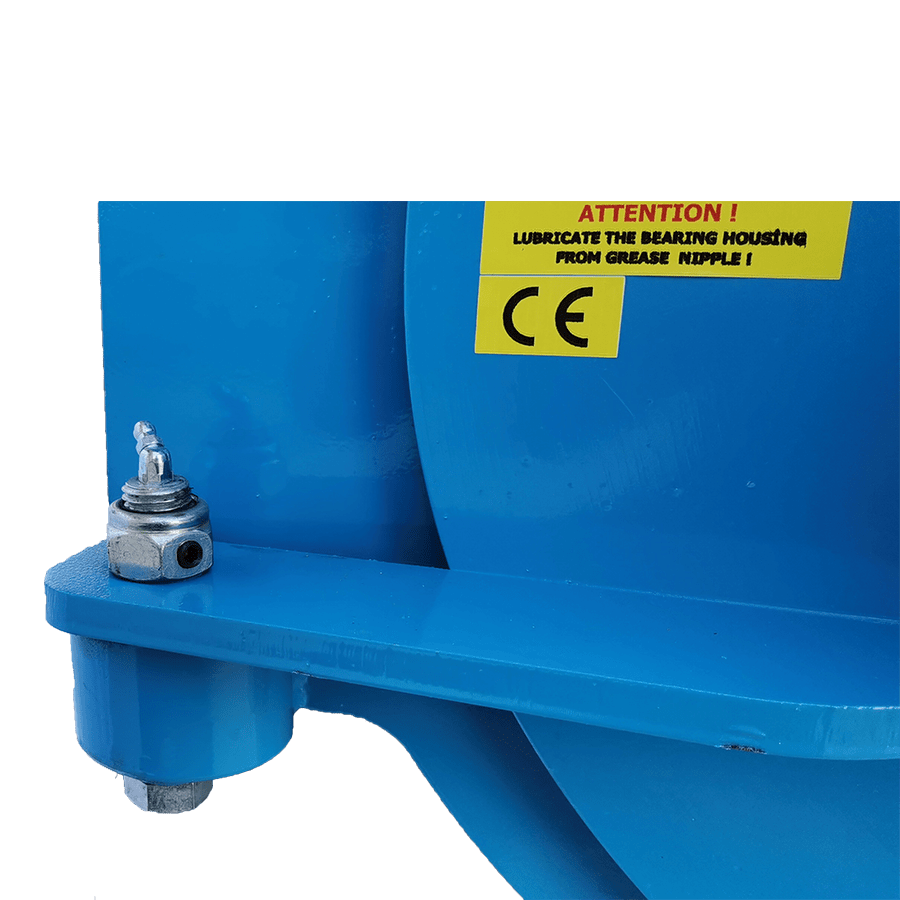

Always pull the plug out of the socket when carrying out, clean ing and maintaining your machine. *Bearing oil maintenance should be done within 30 to 60 days depending on the frequency of use. * If the motor belts are loose, they should be tensioned, and if they are worn, they should be replaced. Every CLEANVAC product is subjected to very detailed control tests by the quality control department. However, the lifetime of a product largely depends on the user. Please read the information in this user manual carefully. If you know the CLEANVAC product you have purchased well, have it maintained regularly and use it in accordance with its purpose, you can be sure that it will serve you safely for many years. The useful life of the product determined by the Ministry of Industry and Trade is 10 (ten) years.

General features

- With shock absorber, 4.2 meters of drum length, 40 cm. drum diameter pipe type carpet wringing machine

- Quiet and smooth running

- Stainless 304 chrome 1st quality steel drum

- 3 mm steel drum thickness

About Product

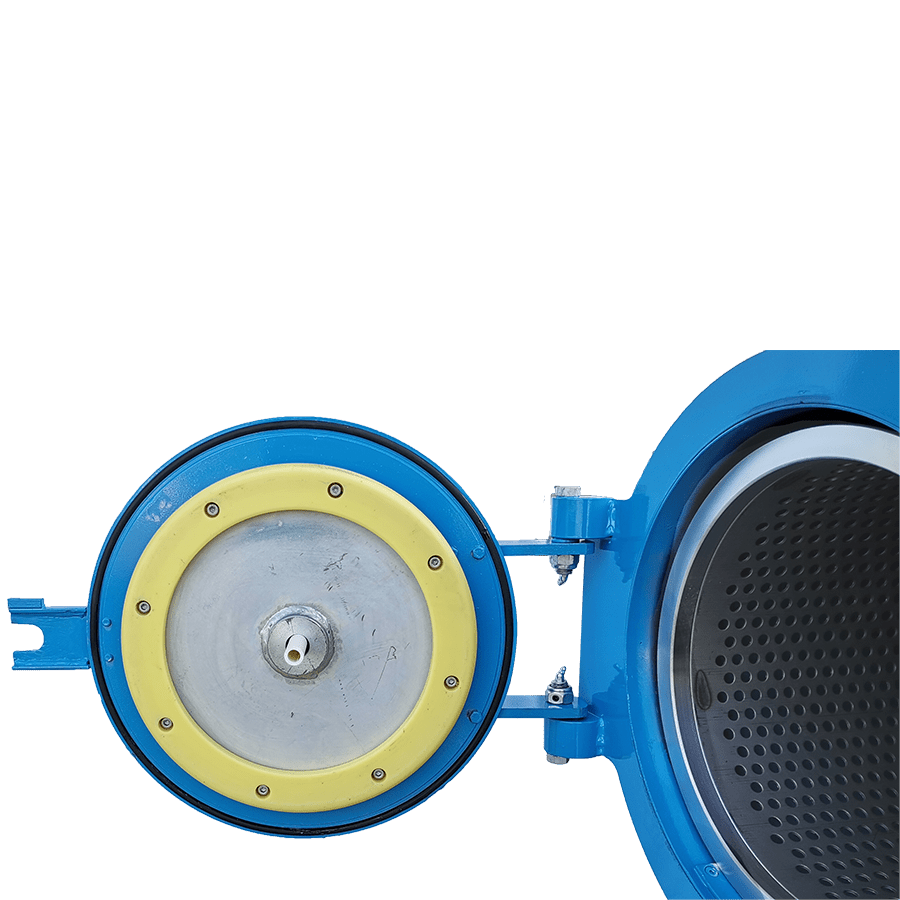

Carpet wringing machines are an indispensable assistant of industrial carpet washing businesses. For this reason, there may be differences in the features and dimensions of carpet spinning machines. In our chrome 1600 A model, which is only one of the types of carpet wringing machines with shock absorbers, the motor power reaching 1400 revolutions per minute and the roller speed reaching 1200 revolutions per minute together with it, ensure that the washed carpets are squeezed out of moisture up to 98 percent. With its 5.5 kW / 7.5 horsepower engine power, it can offer exactly what you want. With its 675 kg weight, the vibration caused by the engine power is absorbed and the machine is prevented from moving. With this machine, carpets up to 420 cm can be easily squeezed. With its 380 V voltage value, it is suitable for use anywhere that uses an industrial electrical network. Due to the fact that it has a shock absorber, the vibration experienced during the tightening process is absorbed and offers a quiet operation. Hourly squeezing capacity is 100m2. It has dimensions of 110x450x155 cm. You can press clean water through the hose from the water tap on the front of the cover. Steam is evacuated from the air holes on the top of the machine. Water is discharged from the Ø60 pipes at the bottom of the machine.

Lid grip system

• The machine works silently and without vibration.

• Tubular type machine does not cause any damage to the carpet due to the way of squeezing the carpet.

• 98 percent dryness is provided in the carpets wrung out with this machine.

• The machine has a carpet rinsing machine feature.

• It helps to achieve perfect fringe cleaning by preventing water from flowing through the eaves during drying.

• Time and labor efficiency increases

• No detergent residues

• Carpets do not have problems such as deformation or breakage.

• Since the carpets do not remain damp for a long time, there will be no bad odor on the carpets.

User Comments

User Comments alanına henüz içerik girişi yapılmadı.

FAQ

| Should Carpet Centrifuges Be Preferred With Shock Absorber Or With Wheels? |

| Every business has its own unique needs. These needs may vary according to the field of study. In cases where it needs to be moved continuously, carpet wringing machines with wheels may be the best choice, and in areas where it can stay at a fixed point, carpet centrifuges with shock absorber can be preferred. In order to overcome this situation, you can get effective information from our customer consultants. |

| What Should Be Considered While Buying a Carpet Centrifuge? |

| Recommended machine speed should be at least 1200 and above. Thus, it may be possible to reduce humidity by up to 95 percent. The thickness of the drum should be 3 mm and chrome. Thus, healthy wringing takes place without tiring the machine. In the selection of the machine, the dimensions vary according to the carpet sizes that the people of the region generally use. |

| Does Carpet Centrifuges Work Quietly? Is it suitable for use under the building? |

| The drum balance is taken on special benches, and it is mounted to the machine as 0 balance with the latest system. The weight and quality of materials such as flanges and bearings used in the cover are the most important factors in reducing noise and vibration. The system we use is suitable for indoor machine use. |

| Does It Dry The Carpet Immediately? What is Average Time? |

| It provides 95 percent dryness in 2-3 minutes with real 1200 cycles. There is a timing option on the board we send next to the machine. |

| What are the Advantages of the Carpet Wringing Machine with Shock Absorber According to the Wheel Model? |

| The first link of the shock absorber system is the shock absorber itself, systems such as bellows are considered inferior quality in this system and are not as effective as a shock absorber in preventing vibration. We minimize the vibration with the shock absorber and thick spring supported system. This means minimum downtime and maximum machine life. |

| What is the Material Used in the Cover? |

| We use cestamite material that prevents wear in the cover system. This system does not deform as quickly as the iron flanged system found in its counterparts and does not cause problems such as iron dust and oil in the machine mouth. |

| What is Drum Quality? |

| Instead of the 2.5 mm and two-piece drum in its equivalents, we use a 3 mm thick original 304 chrome quality drum. With its thickness, it does not cause deformations such as explosion, and its balance is in the best setting thanks to its composition from one piece of sheet metal. |

| Can the Carpet that comes out of the Carpet Washing Machine with Foam be Thrown into the Wringing Machine? |

| With the rinsing system we use on the cover, while it squeezes the carpet, it also removes the remaining chemicals from the carpet completely. |

| While Similar Carpet Centrifuges Have 38 cm Diameter Drum, Why Do You Have 40 cm Diameter? What is the advantage? |

| With the high diameter drum, the best results are obtained on long runners and thick carpets. In addition, with the thick ring we use at the drum mouth, the best drum protection is available. |

| Does it have a board or is it operated with the help of a charter? |

| There is an external electrical panel that can be mounted independently of the machine with a timer inside, thus maximizing work safety, and is timed. |

| What is the Advantage of High Engine kW? |

| More powerful engine is the most important factor in starting power and high kW provides better performance in heavy-duty machines. With the engine power, it generates 1400 cycles of power and transmits it to the drum as 1200 cycles with the pulley system we use. This is the most stable, complete working cycle. In this way, the carpets give the best drying results in a much shorter time. |

| Does Outer Sheet Rust? What is the material? |

| The outer sheet is a single piece of galvanized material and is first primed with epoxy ship primer and then baked in our special paint shops. The longest life is provided in this way. |